The filter fabric selection is an important consideration. If cake washing is critical, the wash solute will diffuse through the filter cake if the cake is thin and the vacuum flow is high. If cake washing is required, the chances of cake cracking from premature dewatering is often by the vacuum level. Compressible cakes, however, may have a high pressure differential which will reduce the production rate. High vacuum levels during cake formation increase cake thickness and yield. But then the cake thickness will be low resulting in a lower production rate.įorm time versus dry time can be precisely managed with the timing position of the bridge blocks internal to the rotary valve. When the low cake moisture is required, then the drum submergence is reduced to offer more dry time. However, the moisture content may be high due to the shorter dry time. High drum submergence will generally yield thick cakes. Operating trade-offs often pose dilemmas for operators. However, the discharge roll and the agitator can indirectly help or hinder the rate.

The production rate is directly determined by the drum speed (measured in “MPR” or minutes per revolution) and drum submergence (or vat level). The drum filter commonly utilizes VFD drives on the drum, on the discharge roll, and on the agitator. The air discharges to the vacuum pump through the top outlet of the tank while the filtrate discharges to a self-priming pump located at the bottom outlet of the tank.

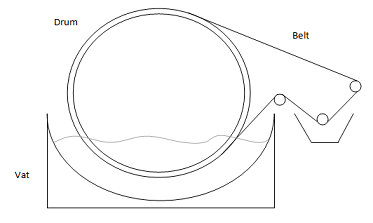

In this tank, the air-filtrate velocity is significantly reduced to allow for separation. In the vat is an oscillating agitator that sweeps the bottom of the vat to uniformly suspend and distribute.įiltrate discharging from the rotary valve flows to a vacuum receiver tank. During cake discharge, the vacuum is released, and the cake is discharged several different ways: belt discharge, scraper with air blow-back discharge, precoat knife discharge, roll discharge, string discharge. The cake now creates a pressure differential that dries the cake to low moistures. During cake drying, the vacuum continues to be applied to the filter cake. During cake formation, the vacuum applied deposits suspended slurry solids on top of the filter fabric. To segregate cake formation from cake drying, the drum is commonly submerged from 10% up to 37.5% in the slurry. The location of the bridge blocks allows control of vacuum where it is most useful and then, with certain designs, to cut off the vacuum when the cake must be discharged. This vacuum control is called the “timing” of the vacuum with the use of adjustable bridge blocks within the valve’s internal cavity. It also allows for vacuum control in the sections of the drum, to segregate cake formation from cake drying from cake washing to cake discharging. The valve body not only directs the liquid filtrate away from the drum. Mounted tight against the rotating pipe plate is a stationary rotary valve that has a sacrificial wear plate which takes the friction between the pipe plate and the valve body. The pipe plate is in effect a manifold for all of the filtrate pipes. The filtrate pipes are welded in an equally spaced pattern to a pipe plate. The filtrate pipes welded to each section are then turned through the inside of the drum to the the non-drive side drum trunnion called the filtrate end. This design promotes high hydraulic rates out of the filter. Each section has its own filter fabric, support grid, and filtrate piping often positioned in leading and lagging parts of each section. Each section is an integral vacuum zone that prevents the leaking of vacuum from one zone to the next. The drum deck is sectionalized into individual division strips to control vacuum without losses.

0 kommentar(er)

0 kommentar(er)